Before the 4th Edition, API 682 did not specify a minimum clearance between the inside diameter of a stationary seal part and the outside diameter of a rotating seal part. The 4th Edition specifies this minimum clearance – typically the clearance between the sleeve OD and the mating ring ID. The clearances specified in 4th Edition are representative of standard clearances that have been used for decades. This is a historical perspective on how those sleeve to mating ring clearances came to be.

I was a member of the API 682 4th Edition Taskforce and had been a member of all the preceding taskforces. In 2008, as we got into the details of revising 3rd Edition into 4th Edition, I was surprised to find a recommendation to include a minimum clearance between the sleeve and mating ring. My surprise was not because there was no need for such a specification but rather because this clearance had not been included in the previous editions. In fact, I do not recall that the topic of clearance between sleeve and mating ring ever came up for discussion during the development of 1st, 2nd or 3rd edition of API 682. Even more significantly, the draft versions of API 682 were widely circulated for comment and eventually API 682 3rd Edition became ISO 21049. During this world wide review and opportunity for comment, at no time was there a recommendation to specify a minimum clearance between the sleeve and mating ring. In a way, this was a comfort to me because I was not the only one who did not think to include sleeve to mating ring clearance in API 682. Even so, I was a bit embarrassed to have overlooked this detail.

A small group of people, some of whom were not on the Taskforce, had made those recommendations to the Taskforce about sleeve to mating ring clearance. In fact, this group forcefully insisted that the 1st Edition of API 682 required a 6mm diametral clearance between the sleeve and mating ring (same as the clearance between the OD of the pumping ring and the bore of the seal chamber). It should be noted that most seal manufacturers had adapted certain seals in their standard product lines to comply with the requirements of API 682. Since API 682 did not include specifications for sleeve to mating ring clearance, many API 682 seals had the same clearance as those standard products – typical on the order of 2 mm diametral clearance. To suddenly, after 14 years of production, require large clearances would be a major change and, in fact, many existing designs could not accommodate 6 mm diametral clearance.

Some members of the “large clearance” group even claimed that seals without 6 mm diametral clearance were not only non-compliant with API 682 but were unsafe. They wanted API to make a statement to that effect. Although the “large clearance” group showed a few examples of sleeve-to-mating ring rubs, they provided no statistics about the incidences of such occurrences. In support of large clearances, Heinz Bloch, the noted technical writer, gave a presentation to the Subcommittee on Mechanical Equipment of API in which he showed an example of a mating ring rub from a non-API 682 seal; however, he did not provide statistics for the incidence of sleeve-to-mating ring rubs. Without data, seal manufacturers were very reluctant to make changes in their products.

Intrigued, I spent considerable time researching the history of API clearances as well as attempting to find published failure analysis statistics or generate statistics of my own. Here’s what I learned and presented to the 4th Edition Taskforce.

Although API 682 1st Edition was radically different from API 610, the 7th Edition of API 610 was used as a point of reference during its development. API 610 7th Edition does not include specifications for sleeve to mating ring clearance. If API 610 7th Edition had specified that clearance then API 682 1st Edition would also have also specified it. But, in fact, no edition of API 610 (dating from the 1950s) includes specifications for sleeve to mating ring clearance.

Prior to API 682 1st Edition, large major corporate end users had their own very detailed specifications for mechanical seals. I reviewed some of those old specifications. None of those end users specified the clearance between sleeve and mating ring. Indeed, if those end users had been concerned about this clearance, that specification would have been placed in API 682 in 1st Edition or thereafter.

How could it be that no one had thought to include this important clearance in the premier specifications for mechanical seals? Was there actually a problem with the status quo? I spent, literally, several days searching for failure statistics about mating ring rubs.

At various times during my career, I have personally inspected many pump/seal failures and have collected data on pump/seal failures. Seeking data for problems with sleeves rubbing mating rings, I pulled old files, memos and summaries of failure distributions for pumps and seals. Just as I recalled, none of my previous collections (databases would not be the appropriate word) included sufficient detail to include a grouping specific to sleeves rubbing mating rings. In other words, I personally had no statistical data about sleeves rubbing mating rings. Even so, based on my experience, I estimated that sleeves rubbed mating rings in less than 1% of seal failures. Statistically, sleeves rubbing mating rings would have been lumped into an “other” group which would have been less than 5% of total failures.

I had written a chapter on seal reliability for the book “Centrifugal Pumps: Design and Application” by Lobanoff and Ross. In that chapter, I included a checklist to aid in seal failure analysis and some statistical causes of seal failures and hardware failures. Although my checklist included a checkbox for “Bushing rubbed” there was no consideration for a mating ring rub. Again, my statistics did not include sleeves rubbing mating rings.

I searched through all the Proceedings of the International Pump Symposium (1984 through 2008) without finding any statistics for sleeves rubbing mating rings.

I searched through four sets of proceedings from Pumps and Systems Magazine PumpUsers Expo without finding any statistics for sleeves rubbing mating rings.

In 2006, the Hydraulic Institute in cooperation with the Fluid Sealing Association published “Mechanical Seals for Pumps: Application Guidelines”. That book does not contain any statistics for sleeves rubbing mating rings. Chapter 9 is about mating rings but does not mention clearances. Chapter 23, “Troubleshooting Mechanical Seals”, does not mention sleeves rubbing mating rings.

I searched through Heinz Bloch’s four book set, “Practical Machinery Management for Process Plants” without finding any statistics for sleeves rubbing mating rings. In 2005, I contributed data regarding Mean Time Between Failures for Heinz Bloch’s book, “Pump User’s Handbook” and Neil Wallace also contributed a section on MTBF. There were no statistics for sleeves rubbing mating rings. This book contains an appendix, “A ‘Hundred-plus Points’ Summary of Pump Reliability Improvement Options and Considerations”; however, clearance between the sleeve and mating ring is not mentioned. The book also contains an appendix, “Supplementary Specification for API – Class Pumps” to be used as a guideline for developing end-users specifications; however, this appendix does not mention clearance between sleeve and mating ring. Considering Heinz’s volume of work, I could easily have missed his data on mating ring rubs but it seemed to me that Heinz did not have any statistical data on sleeves rubbing mating rings.

With all the above in mind, my conclusion was that contact between the sleeve and mating ring was rare. In fact, rare enough that it was easily overlooked during the development of both API 610 and API 682. Rare enough that incidences of contact have been lumped into an “other” category of symptoms by industry experts and associations. Therefore, it was easy to conclude that the clearances currently being used by the seal manufacturers must be adequate. I presented the results of my research to the 4th Edition Taskforce. At the same time, I agreed that API 682 4th edition should specify a minimum clearance between sleeve and mating ring. I recommended that the clearance should be representative of typical clearances currently being used.

Unfortunately, somehow the “large clearance” group interpreted my presentation as a statement that I had never seen an incidence of a sleeve rubbing a mating ring. That interpretation was absurd. I was simply saying that I could find no existing statistical data about this problem. The Taskforce discussions and debates became increasingly acrimonious. Legal action was threatened by some members of the “large clearance” group. Legal counsel for API, some end users and some seal OEMs began to attend Taskforce meetings. This was by far the most contentious issue of my career.

Although the Taskforce discussed collecting data and developing its own statistics, the API legal caution was that all surveys, studies, etc that are done in the name of API must follow strict API procedures and must be cleared in advance by the API. With that caution in mind, the Taskforce did not initiate a survey. However, I did.

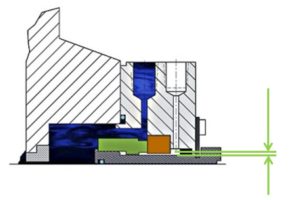

I assembled a database of some 19,000 seal repairs and searched for repairs in which the throttle bushing and/or mating ring had been touched by the sleeve. The database included seals from all the OEMs on the Taskforce although most were from one manufacturer. Most of these seals were cartridge type arrangements but not necessarily true API 682 seals. For this database, 1.6% of the seals had some sort of “touch” of the fixed throttle bushing and 0.3% had some sort of “touch” of the mating ring. Those throttle bushings would have had a nominal 0.025” diametral clearance. Those mating rings would have had, by my judgment, approximately 0.060” diametral clearance. There were 59 mating ring rubs; 13 of these were associated with bearing failures. I examined most of the layout drawings for these 59 seals. Only 5 mating ring rubs occurred on API 682 seals and 2 of those were associated with a bearing failure; the other 3 rubs were associated with severe misalignment during installation. There were a few dual seals which had mating ring rubs during a bearing failure in spite of having large clearances. All 59 mating ring rubs are included in the 0.3% mating ring rub statistic.

I then queried a database of some 100,000 seal repair summaries in search of pumping ring rubs. The query showed 121 (0.12%) incidences of pumping ring rubs. The majority of those pumping rings would have had a clearance of approximately 0.040 inch (diametral).

From these studies, I concluded and estimated that the statistics for mating ring rubs are or would be

- 0.14 to 1.6% if a nominal 0.025 inch diametral clearance were used

- 0.12 to 0.16% if a nominal 0.040 inch diametral clearance were used

- 0.024 to 0.30% if a nominal 0.060 inch diametral clearance were used.

I did not present my own statistics to the Taskforce but held them ready in hopes of adding them to studies made by other Taskforce members. However, no one provided such statistics although perhaps other such studies were made and retained as mine were. Whatever the case, a proposal was made to adopt the following minimum clearances between sleeve and mating ring:

- For shafts <= 60mm diameter, minimum diametral clearance is 1 mm (0.039 inch)

- For shafts > 60mm diameter, minimum diametral clearance is 2 mm (0.079 inch).

These clearances are somewhat representative, perhaps slightly larger, of conventional seal designs. A Taskforce vote was held and the proposed clearances were accepted (with one “No” vote) and included in API 682 4th Edition in Table 1 of Section 6.

It should be emphasized that the minimum clearance specified in API 682 4th Edition applies only to equipment within the scope of the standard. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.