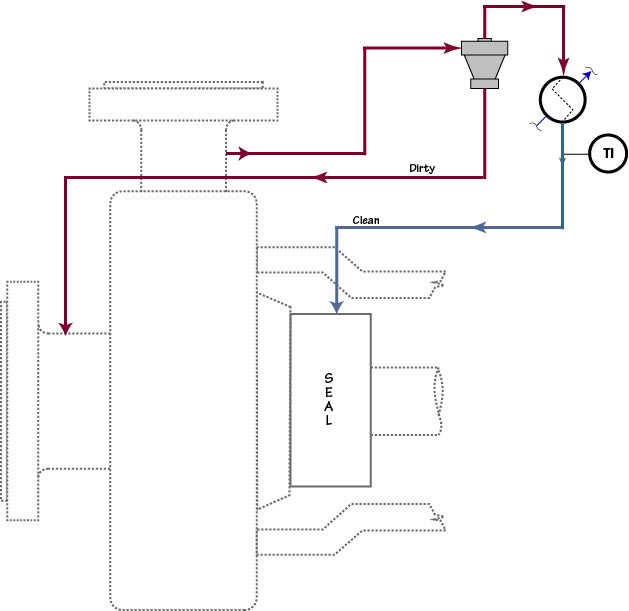

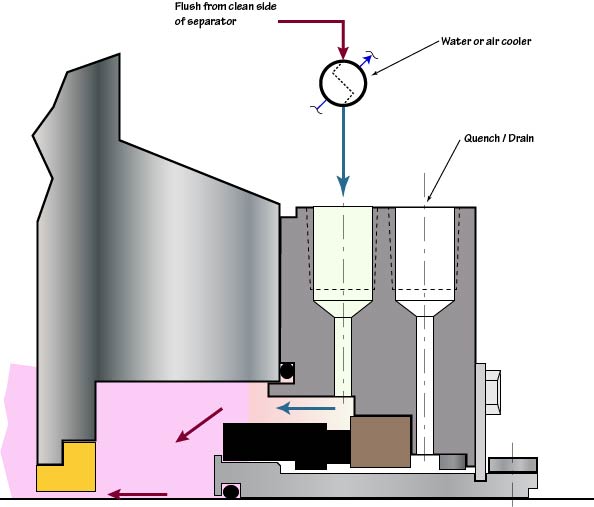

Plan 41 is a combination of piping Plan 21 and Plan 31. In Plan 41, the product, flowing from pump discharge, first goes through an abrasive separator to eliminate solid particles, and then to a heat exchanger to reduce the temperature before being introduced into the seal chamber. Optional accessories are an orifice to control the flow and a temperature indicator on the product outlet side of the heat exchanger. In some installations temperature indicators are also used to monitor cooling water temperatures. Like Plan 31, Plan 41 should only be used for services containing solids that have a specific gravity at least twice that of the process fluid. Throat bushings are a requirement when using this piping plan because the throat bushing isolates the cool, clean fluid surrounding the seal faces from the pumpage.

Plan 41 is not very popular because it is very difficult to pipe properly to obtain the correct flow rate through the abrasive separator and the heat exchanger.