Seal qualification testing is an attempt to demonstrate that the mechanical seals offered in compliance with API 682 have a reasonable assurance that they can meet the performance and life expectations in the standard. While this seems to a trivial matter, the reality is that it requires a thoughtful approach to address the many different options, designs features, materials, arrangements, and seal types available in the standard. This process began with liquid seal qualification testing in the First Edition and expanded to include gas seal and containment seal testing in the Second Edition. While most of the qualification testing remains the same as previous editions, the Fourth Edition introduced a few new requirements and test procedures.

One of the challenges for seal OEMs is to perform the required testing for the correct options. There are literally thousands of combinations of variables which could be tested. Seal OEMs have invested millions of dollars in testing to comply with the standard and it is problematic to introduce new test requirements especially if it voids previously valid testing. For this reason, API 682 has created a common sense balance between testing and benefits. One of the methods used to achieve this is to allow for evaluating “core seal components” and then reusing them in different designs without additional qualification testing. The problem within the standard was that it did not specifically define what is considered “core seal components.”

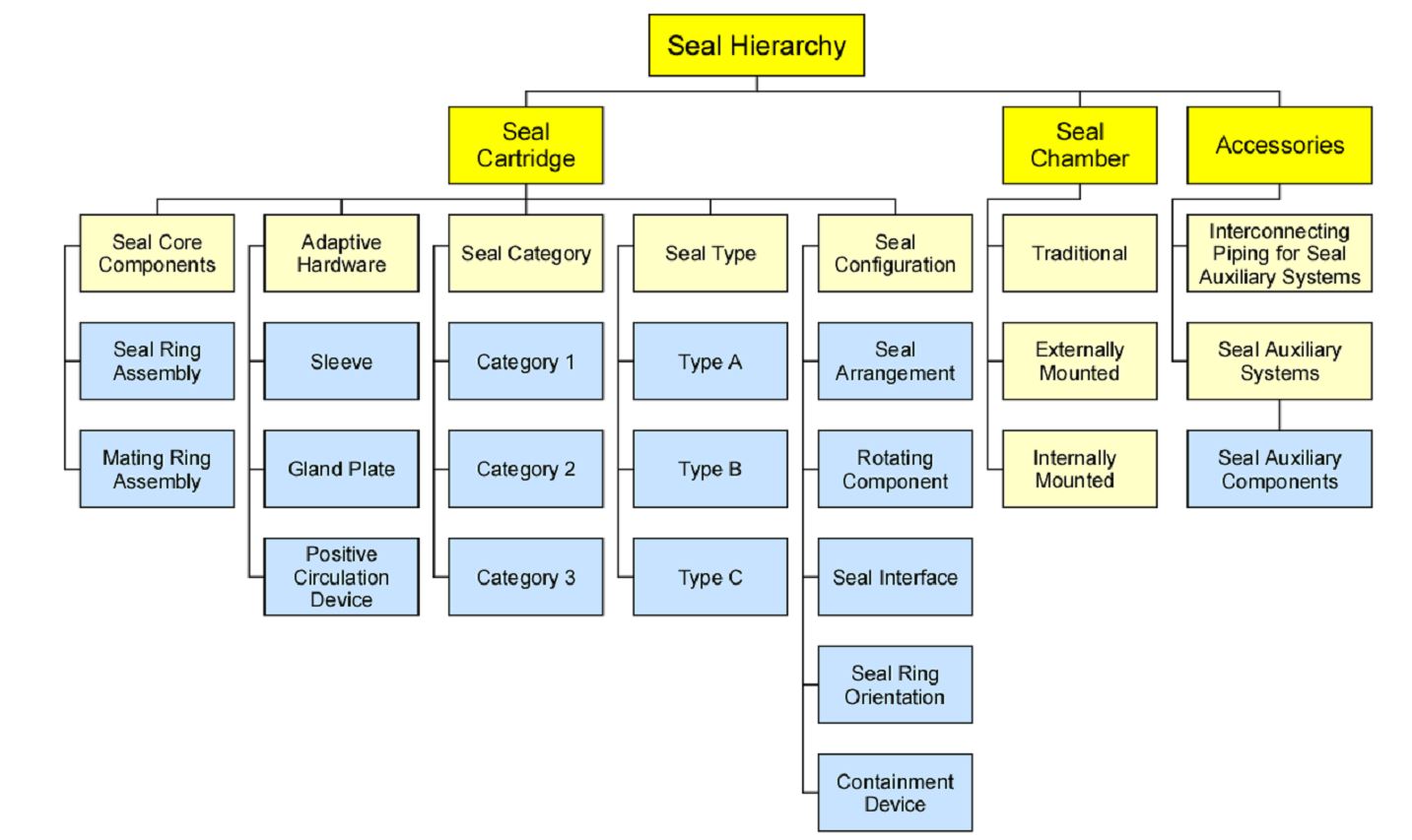

The Fourth Edition addressed this problem by setting up a hierarchy of seal parts. The core components consist of the seal ring and mating rings. Adaptive hardware consists of sleeves glands and circulating devices. Seal Categories, Types, Configurations complete the description of the seal cartridge. These definitions are used to describe how core seal components can be shared among different seal models and categories.